Nottingham Contemporary - initially called CCAN or Centre for Contemporary Art Nottingham.

Nottingham Contemporary - initially called CCAN or Centre for Contemporary Art Nottingham.Architects - Caruso St John.

Plan to incorporate the lace design into a concrete facade, to reflect on the history of the area of Nottingham known as the Lace Market. This area was home to Richard Birkin and Thomas Adams lace factories during the 19th century.

The design chosen by the architects was from a sample book, of 1847, by Richard Birkin, a piece of machine made Valenciennes lace, which had been found buried in an antique time capsule. (Now in collections of the Nottingham museums.)

I became involved in this project when the architects wanted the original machine made lace by Richard Birkin, recreating in handmade bobbin lace, but at ten times the original scale.

The brief was to make this lace in thick cord, which would be used to cast a rubber mould from (by Reckli in Germany) and then to cast the concrete panels from this.

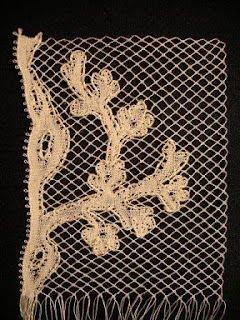

Scan of the original lace.

Scan of the original lace.Size approx 50mm wide.

My first sample - I initially worked a small sample of this lace at the original scale, to get a feel for the lace, to simplify the design and to find any problems I was going to encounter on working the larger scale design.

The lace has a slightly different appearance due to the fact this is hand made and so the techniques for hand made Valenciennes are not quite the same as is possible on the machine lace.

My next sample was at the scale required for this commission, and shown here with the above sample next to it.

The design had to be simplified to make it possible to work it in this thick cord. (The cord was actually created with a braiding machine, using 8 strands of thread. Commercially available cord was tried but found to have too much twist to work well.)

This sample worked in cord that was approx 2mm thick.

It was decided that due to the production methods being used, the round profile of the cord was going to cause problems and the following work was carried out using advanced digital imaging and laser technology, within the university, where I was studying at the time, to replicate the design which was subsequently used for the facade of this building

The finished design work which was used for the facade.

And how it looks translated into the panels...

Panels were cast in Nottingham by Trent Concrete.

Also see http://www.derby.ac.uk/textiles/news/contemporary-arts-building

Great to see your work here, interesting to see the various stages you went through explained. I'm so proud of you. Jan

ReplyDeleteI really like this and now want to carry around lace at all times in case I see a wet concrete space somewhere...

ReplyDelete